High-Strength Small Magnets: Rare Earth Solutions for Compact Spaces

Rare earth magnets are by far the strongest magnets available. They are made from rare earth elements and typically 10mm or smaller, with the most popular being neodymium magnets. Despite their small size, micro magnets have extraordinary magnetic strength, and they are the main power source for electronics, medical devices, industrial applications, household products, and emerging technologies. The high power and small size of these magnets make them an essential part of modern technology and everyday life.

Characteristics of small Rare Earth Magnets

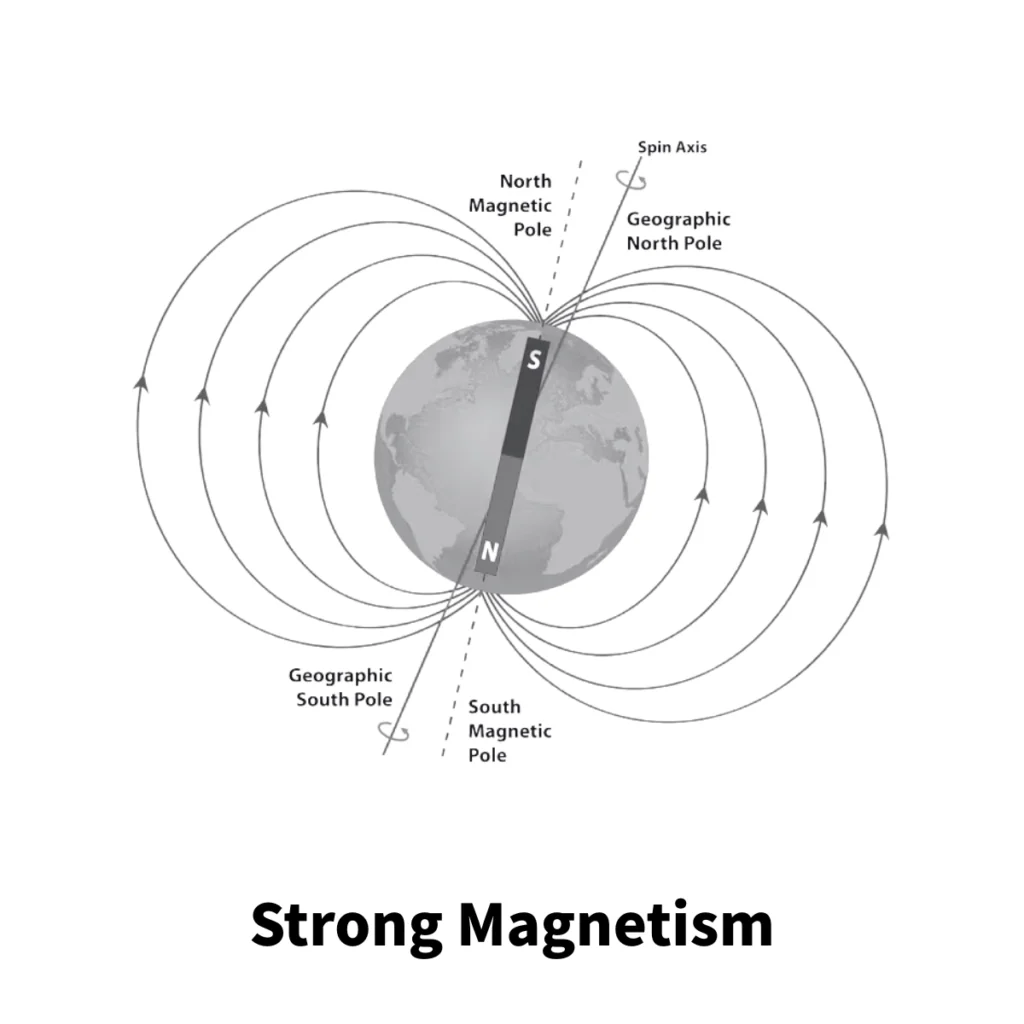

Strong Magnetism

Miniature NdFeB magnets are able to produce extremely strong magnetic fields in a very small volume, making them ideal for applications that require strong magnetic forces in a small space. The strong magnetic properties of these magnets also help improve equipment efficiency and reduce energy losses.

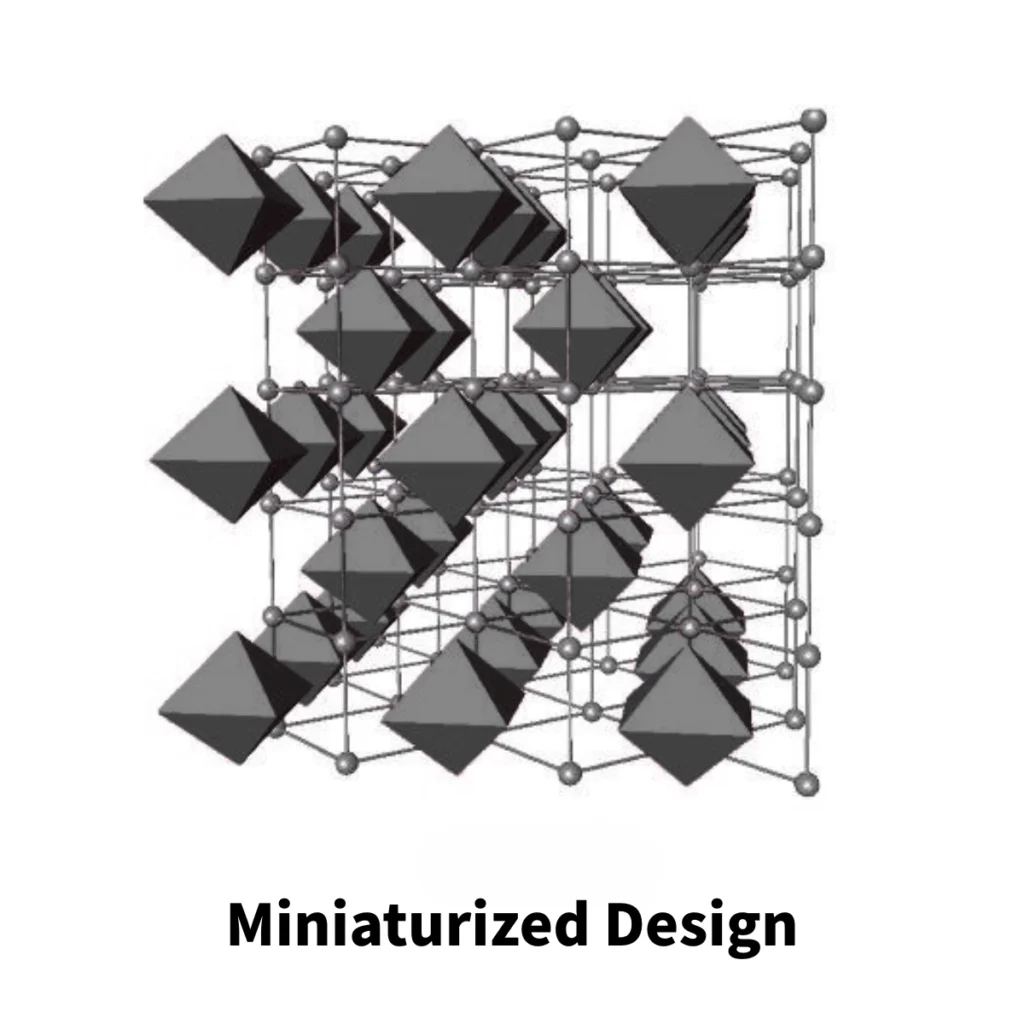

Miniaturized Design

The main feature of miniature NdFeB magnets is their small size. They can easily enter narrow spaces that ordinary magnets cannot enter.

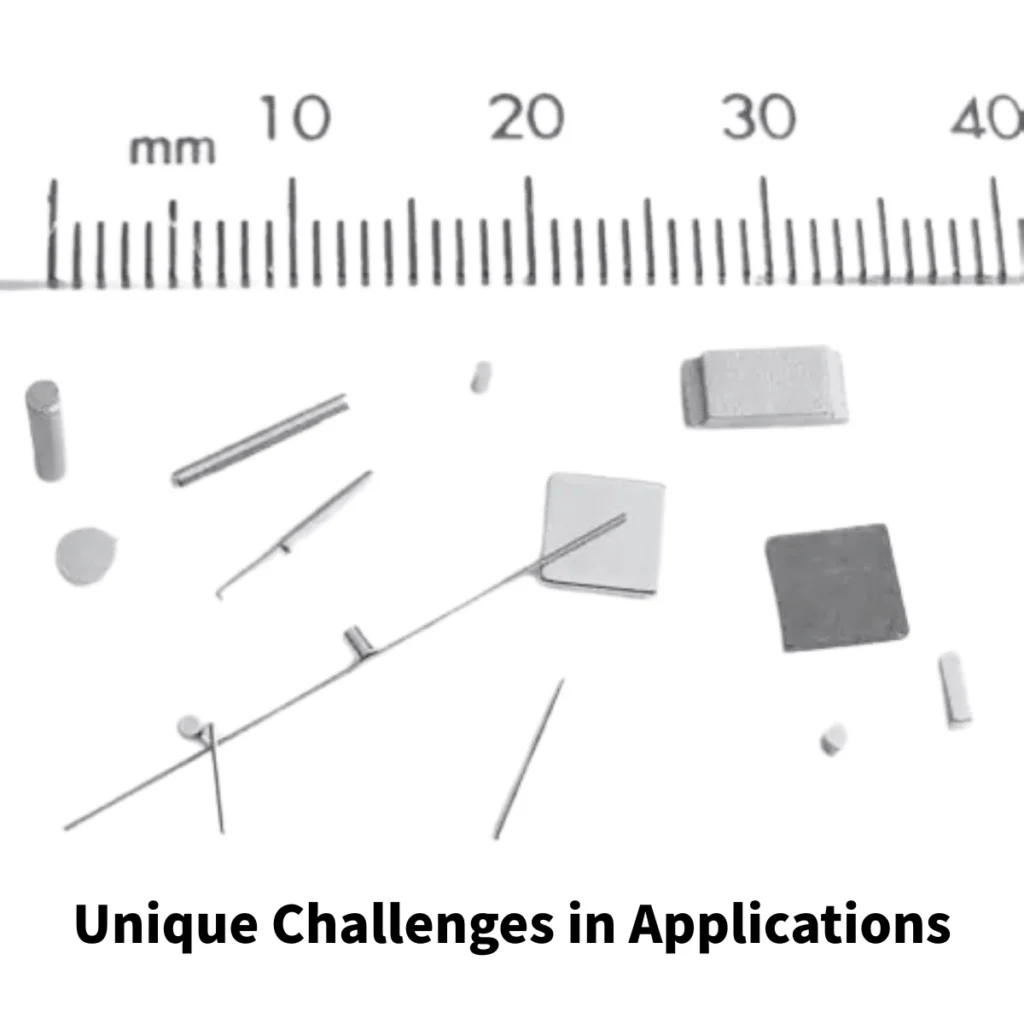

Unique Challenges in Applications

The small size of miniature NdFeB magnets also brings some limitations, the most notable of which is their low corrosion resistance. Uncoated magnets are more likely to rust in high-humidity environments and need to be protected in some way during use. The reduced size also reduces the mechanical strength, making it more fragile, and it must be handled carefully during processing and installation to avoid any cracking and damage to the magnets.

Wide Applications of small Rare Earth Magnets

Hard Disk Drives (HDD): Provide strong magnetic fields for fast data reading and storage.

True Wireless Stereo (TWS) Earbuds:Circular or block-shaped magnets secure earbuds and ensure charging case closure, enhancing user experience.

Speakers: convert electrical signals into high-quality sound waves, which are widely used in high-fidelity audio systems and earphones.

Hearing Aids:Miniaturized design ensures lightweight and efficient devices.

Workpiece Fixturing:Secure irregular parts in CNC machining for precise processing.

Crafts and DIY: Used in scrapbooking, jewelry clasps, model making, and children’s science experiments.

Proximity Sensors: Detect object positions in robotics, automation, and security systems.

Reed Switches: Control circuit switching through magnetic field changes, widely used in electronic devices.

Hall Effect Sensors: Used in automotive and industrial applications for speed or position detection.

Electric Guitar: smallmagnets capture string vibrations for transmission to amplifiers, delivering clear sound quality.

Microphones: Enhance the efficiency of sound signal conversion.

Guide to Selecting Small Rare Earth Magnets

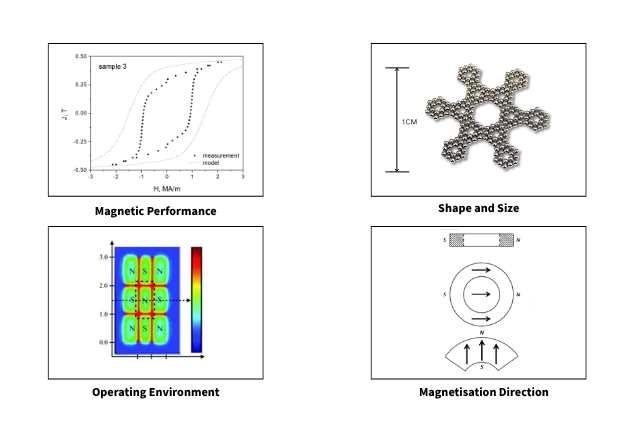

Magnetic Performance:

In the process of selecting small rare earth magnets, the important factors are coercivity, remanence and magnetic energy product.

Shape and Size:

The shape and size of miniature rare earth magnets must be as consistent as possible with the desired shape before they are manufactured. Round, cubic, cylindrical, or special-shaped magnets must fit into small spaces. Due to their small size, miniature magnets are usually more difficult to process.

Operating Environment:

small rare earth magnets are highly sensitive to the conditions of their working environment. Neodymium magnets in small magnets work normally at temperatures below 80°C, and due to their small size, they lose their magnetism quickly above this temperature. In addition, if the working environment is humid, the magnets are easily corroded.

Magnetisation Direction:

The magnetisation direction is an important consideration in the selection of micro rare-earth magnets. Common magnetisation directions are axial, radial, or thickness magnetisation to ensure that the magnet can perform optimally. Due to the small size of small magnets, the accuracy of their magnetisation direction may have a greater impact on device performance, so the most suitable magnetisation direction needs to be carefully evaluated and selected.

Small Rare Earth Magnet Supplier

Are you looking for a reliable supplier of small rare earth magnets? At TOPMAG, we specialise in providing customised rare earth magnet solutions.

The TOPMAG team tailors recommendations to your specific project needs, from shape and size to magnetisation direction, ensuring the magnets precisely meet your requirements.

I'm dedicated to popular science writing about magnets. My articles mainly focus on their principles, applications, and industry anecdotes. Our goal is to provide readers with valuable information, helping everyone better understand the charm and significance of magnets. At the same time, we're eager to hear your opinions on magnet-related needs. Feel free to follow and engage with us as we explore the endless possibilities of magnets together!