Alnico Magnet Thermal Stability Solutions

In the 1930s, General Electric created alnico magnets by mixing metals like aluminum, nickel, cobalt, and iron, which drastically improved the strength and stability of permanent magnets that were used instead of traditional steel and iron magnets. Before the 1970s, alnico magnets were the strongest permanent magnets available, widely used in electronics, automotive, and telecommunications industries.

Alnico magnets are a classic type of permanent magnet, widely favored in industries such as aerospace, automotive, and medical for their excellent high-temperature stability, corrosion resistance, and strong magnetic fields. Although rare-earth magnets (such as neodymium and samarium-cobalt) surpass them in magnetic strength, alnico magnets have regained attention in recent years for high-demand applications due to their reliability in high-temperature environments and cost-effectiveness. Since its establishment in 2004, TOPMAG has become a leader in alnico magnet manufacturing, with its products seeing growing applications in the aerospace and automotive sectors.

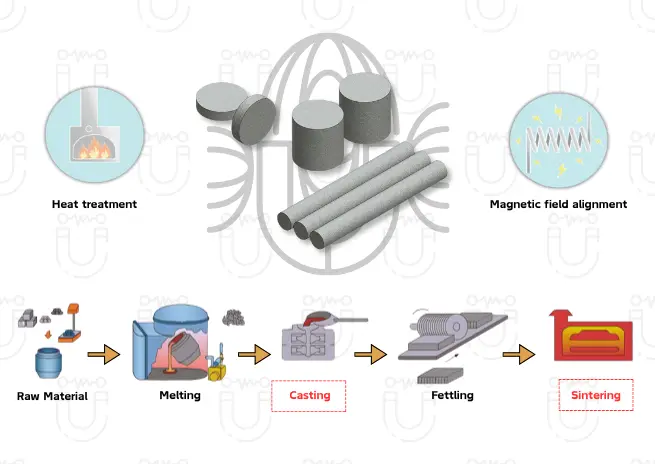

Main Composition and Manufacturing Process

The creation of Alnico magnets mainly involves two major procedures: casting and sintering.

Casting Process: A molten alloy is poured into molds to form the desired shape, which is a very suitable technique for producing magnets of complex geometries such as horseshoe or ring-shaped magnets that are the most common in guitar pickups and aerospace sensors. The casting process offers several advantages, one of which is high flexibility, whereby accommodating big or non-standard shape customization needs is possible.

Sintering Process: In this procedure, metal powders are compacted and thereby sintered at high temperatures(in an inert atmosphere) to produce magnets with improved mechanical strength and high precision. This method is mainly applicable to situations that require a high degree of consistency and miniaturization.

However, it does not matter if they employ casting or sintering. The magnets usually go through heat treatment and magnetic field alignment after forming to improve the magnetic domain alignment, thus increasing remanence and coercivity for better magnetic performance.

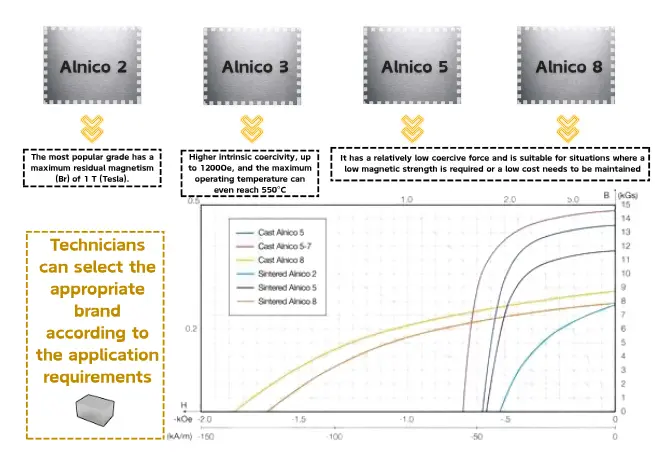

Grades and Characteristics of Alnico Magnets

Alnico 5 is the most popular grade with a remanence (Br) of 1 T (tesla) at the maximum that can create a magnetic field of high strength, which is suitable for the most demanding tasks requiring magnetic flux of high intensity. The high remanence of Alnico 5 gives it a top performance in devices that need a stable magnetic field.

Alnico 8 has higher intrinsic coercivity, up to 1200 Oe. Thus, it is able to provide a strong resistance to demagnetization, which makes it especially perfect for high-temperature and short magnetic axis design. Its maximum operating temperature may even be 550°C. Thus, the device can work without problems, even in harsh conditions.

Alnico 2 and Alnico 3 are suitable for those situations where lower magnetic strength is required, or there is the need to keep the cost low. Due to their lower coercivity, they are perfect for guitar pickups that sound warm and vintage, the tones mostly liked by blues and jazz musicians. For more detailed parameters, please visit alnico magnets.

Effect of Temperature on the Performance of Alnico Magnets

Temperature is a major factor which influences the behaviour of permanent magnets, and Alnico magnets are particularly famous for their excellent thermal stability in high-temperature environments. The change in magnetic characteristics of Alnico magnets at various temperatures is primarily influenced by their temperature coefficients, along with the temperature coefficients of remanence (Br) and intrinsic coercivity (Hci). These features give Alnico magnets the capability to maintain magnetic performance without significant degradation in severe temperature conditions. In particular, they are very suitable for high-temperature applications, such as jet engine sensors and electric vehicle motors, because they frequently remain competitive against rare-earth magnets.

Alnico magnets have an almost negligible temperature coefficient of remanence of only -0.02% per °C (within the range of -0.035% to -0.025%), which indicates that the decrease in magnetic induction intensity is very small with the rise of temperature.

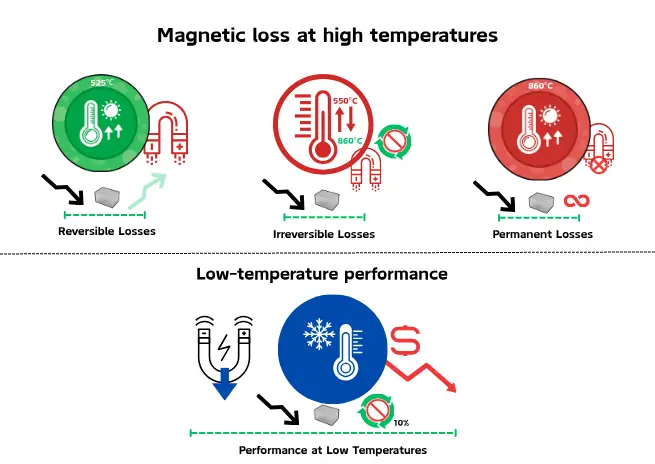

Magnetic Losses at High Temperatures

The changes in the magnetic performance of Alnico magnets under high-temperature conditions can be categorized into three types: reversible losses, irreversible losses, and permanent losses.

1.Reversible Losses

When the operating temperature is below the maximum working temperature of Alnico magnets (approximately 525°C), the magnetic performance temporarily decreases as the temperature rises but fully recovers upon cooling to room temperature. This reversible loss is primarily due to slight misalignments of magnetic moments caused by thermal motion without permanent changes to the magnetic domain structure.

2.Irreversible Losses

When the temperature exceeds 550°C but remains below the Curie temperature (approximately 860°C), Alnico magnets experience partial irreversible losses, meaning the magnetic performance cannot fully recover after cooling. These losses are typically caused by partial rearrangement of the magnetic domain structure or an increase in microscopic crystal defects. The extent of irreversible losses is generally less than 5%, depending on the magnet’s geometry, magnetic circuit design, and exposure time.

3.Permanent Losses

When the temperature exceeds the Curie temperature (approximately 860°C), the magnetic domain structure of Alnico magnets is completely destroyed, resulting in permanent loss of magnetic performance. The Curie temperature is the critical point at which the magnet loses its magnetism, as thermal energy fully disrupts the ordered arrangement of magnetic moments.

Performance at Low Temperatures

In cold environments, Alnico magnets exhibit one of their characteristic properties. Because the thermal motion of molecules is reduced, the magnetic moments become more ordered, effectively focusing the magnetic field and giving the magnet’s performance a slight enhancement. However, at extremely low temperatures, an irreversible loss in magnetic strength of approximately 10% may occur in Alnico magnets, primarily influenced by the shape of the magnet and the design of the magnetic circuit.

Comparison of Temperature Characteristics with Other Magnets

Alnico magnets outperform many other permanent magnet materials at both high and low temperatures, making them highly favoured in non-rare-earth magnet applications.

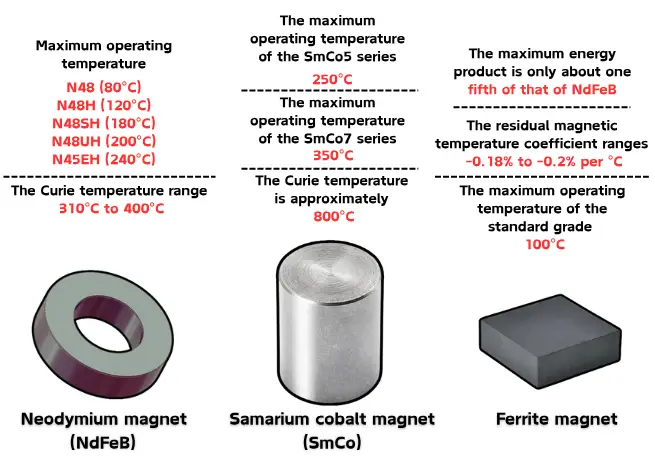

1.Neodymium Magnets (NdFeB):

NdFeB magnets have the highest remanence, making them the strongest commercially available permanent magnets. However, they are highly temperature-sensitive, with a remanence temperature coefficient of -0.08% to -0.12% per °C. Different grades correspond to different maximum operating temperatures: N48 (80°C), N48H (120°C), N48SH (180°C), N48UH (200°C), and N45EH (240°C). Their Curie temperature ranges from 310°C to 400°C, depending on the grain boundary diffusion process.

2.Samarium Cobalt Magnets (SmCo):

SmCo magnets exhibit better high-temperature performance than NdFeB. The SmCo5 series has a maximum operating temperature of 250°C, while the Sm2Co17 series can reach 350°C, with a Curie temperature of approximately 800°C. SmCo magnets offer excellent corrosion resistance, making them suitable for high-reliability applications such as aerospace.

3.Ferrite Magnets:

Ferrite magnets have lower remanence, with a maximum energy product only about one-fifth that of NdFeB, but their intrinsic coercivity increases with temperature, providing excellent demagnetization resistance at high temperatures. Their remanence temperature coefficient is -0.18% to -0.2% per °C, and standard grades have a maximum operating temperature of 100°C. Ferrite magnets are cost-effective but have weaker magnetic strength, making them suitable for applications with lower magnetic performance requirements.

Main Applications of Alnico Magnets

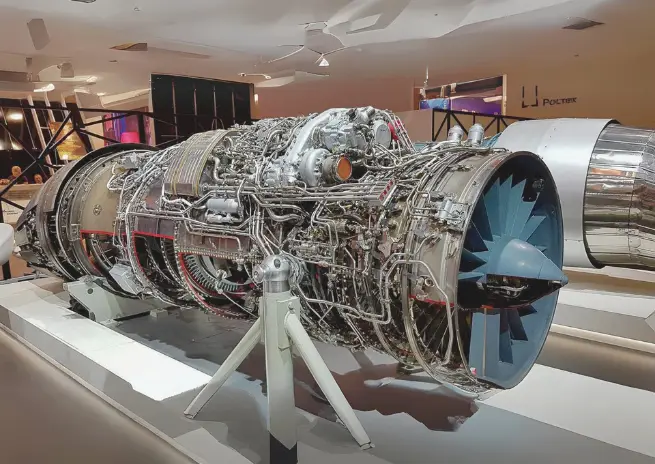

Aerospace

Alnico magnets are an essential part of jet engine sensors, gyroscopes, and navigation equipment, and they are considered the most critical components. Alnico 8, which has exceptional coercivity and can operate at extremely high temperatures (525°C), is the primary material used in engine sensors of the Boeing 787, ensuring reliable signal transmission even in hostile environments.

Automotive Industry

In the electric vehicle (EV) sector, Alnico magnets are used in power steering systems, alternators, and sensors. Alnico 5, which exhibits high remanence and cost-effectiveness, is most frequently used in tachometers and speedometers to provide a stable magnetic field.

Industrial Applications

Alnico magnets are used in motors, generators, and magnetic separators, and they perform optimally in high-temperature industrial environments.

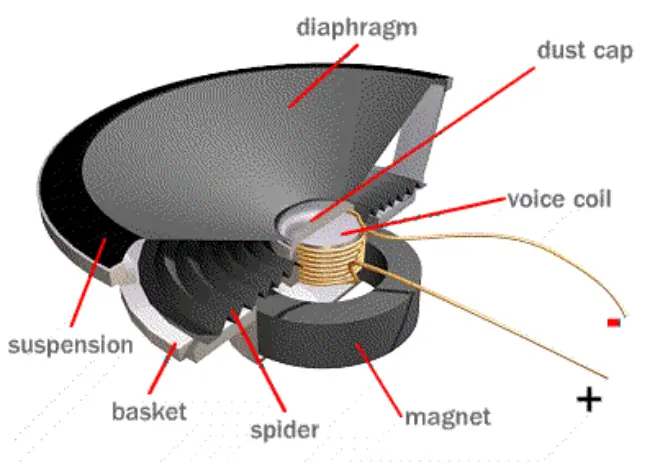

Electronics and Telecommunications

Alnico magnets are present in speakers, microphones, and travelling wave tubes, ensuring efficient signal amplification. Their high remanence guarantees sound clarity, particularly when the equipment is designed for high-fidelity audio systems.

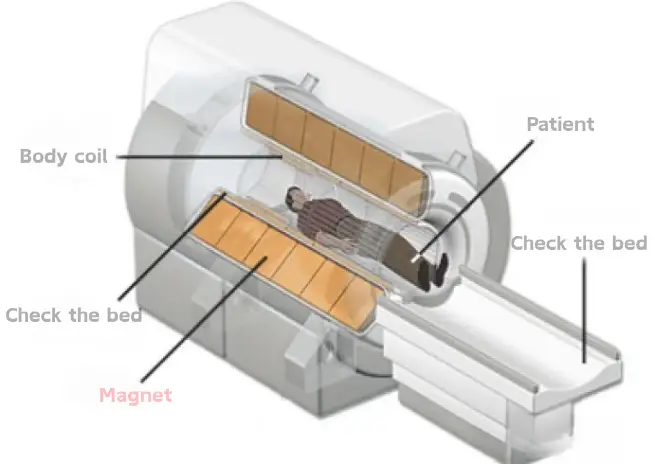

Medical Equipment

Alnico magnets are utilized to provide stable magnetic fields and exhibit biocompatibility in MRI machines. Furthermore, their high-temperature stability ensures they maintain performance during prolonged operation.

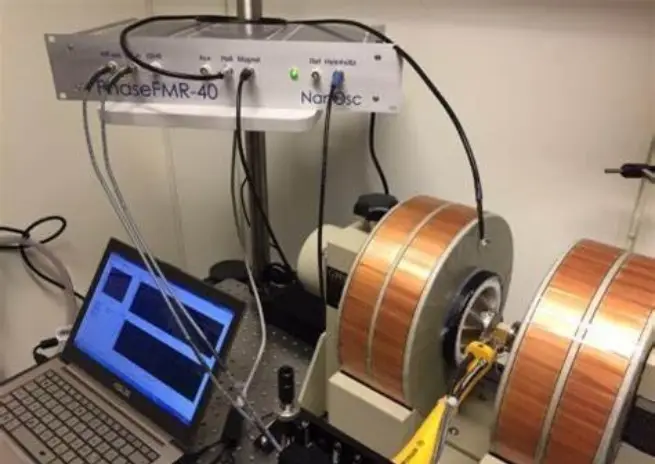

Scientific Instruments and Education

Alnico magnets are used in mass spectrometers and particle accelerators to maintain precise magnetic fields. Additionally, in educational settings, they are employed in demonstration experiments to illustrate magnetic principles.

Music and Guitar Pickups

For their warmth and vintage character, which have become synonymous with blues and rock genres, Alnico magnets are widely adopted in guitar pickups. Alnico 2 delivers a mellow tone ideal for jazz, whereas Alnico 5 produces a bright tone with a distinctive dynamic response.

How to Select Alnico Magnets

1.Choose the Appropriate Magnet Grade and Shape

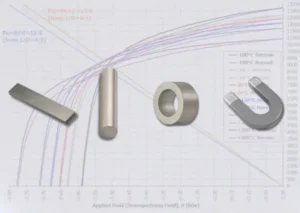

Alnico magnet types are generally classified into different grades, such as Alnico 2, Alnico 3, Alnico 5, and Alnico 8, depending on composition and heat treatment, which determine their magnetic performance and application suitability. The magnet’s shape and size are the most critical factors influencing magnetic field distribution and also affect resistance to demagnetization. Typical magnet shapes include bar, rod, ring, and horseshoe. Among these, long cylindrical magnets (with a length-to-diameter ratio of approximately 4:1) are considered to have the best resistance to demagnetization due to their stable magnetization direction.

2.Cost and Cost-Effectiveness Analysis

Alnico magnets are generally priced higher than ferrite magnets. However, their superior performance at high temperatures, longer lifespan, and stronger magnetic fields make them more cost-effective in the aerospace and automotive industries.

I'm dedicated to popular science writing about magnets. My articles mainly focus on their principles, applications, and industry anecdotes. Our goal is to provide readers with valuable information, helping everyone better understand the charm and significance of magnets. At the same time, we're eager to hear your opinions on magnet-related needs. Feel free to follow and engage with us as we explore the endless possibilities of magnets together!