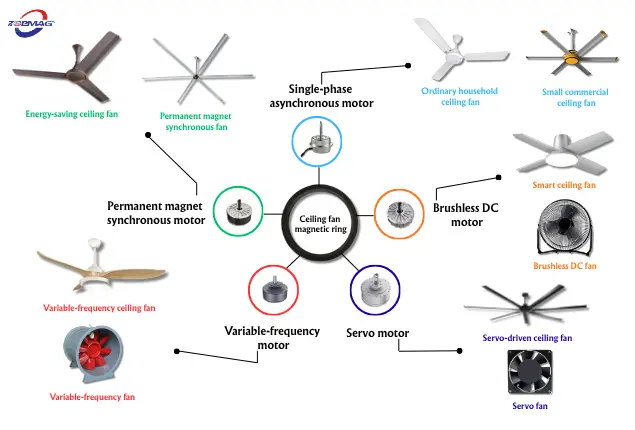

Custom Ceiling Fan Magnets for Energy-Efficient BLDC Motors

Our ceiling fan ring magnets are specifically designed to upgrade BLDC motors, reducing energy costs by 70%. These permanent magnets are suitable for a variety of design styles in both residential and commercial ceiling fans. Contact us immediately, we will provide a free evaluation of your specifications and offer over 100 molding options to help you save on development costs.

These magnets are tailored for BLDC motors that comply with IEC 60335-1 safety standards for household appliances, ensuring the entire unit operates safely and efficiently. Use our magnets, your BLDC ceiling fans will easily meet India’s BEE energy efficiency standards, enabling you to swiftly achieve 5-star certification and gain a competitive edge in the market.

What Are Ceiling Fan Magnets?

Ceiling fan magnets are an indispensable ring-shaped permanent magnet installed inside a brushless DC motor. They form an integral body composed of alternating N poles and S poles. The magnetic field changes induced by energizing the stator windings interact with the rotor’s permanent magnets, thereby generating the magnetic force that drives the motor to rotate smoothly. For household and industrial ceiling fans, this design can reduce noise to below 30 decibels, greatly enhancing user comfort.

Ceiling fan magnets are an indispensable ring-shaped permanent magnet installed inside a brushless DC motor. They form an integral body composed of alternating N poles and S poles. The magnetic field changes induced by energizing the stator windings interact with the rotor’s permanent magnets, thereby generating the magnetic force that drives the motor to rotate smoothly. For household and industrial ceiling fans, this design can reduce noise to below 30 decibels, greatly enhancing user comfort.

Benefits of Upgrading Traditional Fans

Upgrading traditional ceiling fans typically requires substantial R&D investment and unit replacements, which presents a major hurdle for ceiling fan manufacturers. However, our magnet solution enables rapid upgrades at extremely low cost. Unlike single-function control controllers, our injection molded magnet rings can simultaneously enhance the fan’s efficiency, airflow, and energy-saving performance across multiple dimensions.

Moreover, compared to complex variable-frequency motors, our ceiling fan magnets achieve similar energy saving effects with only simple magnetic field optimization, making injection molded magnet rings particularly ideal for budget-constrained markets.

How to Get Your Custom Solution:

- Send your fan design details to verify compatibility.

- Receive a customized quote within 24 hours.

- Upon confirmation, begin production and integration testing.

| Feature | BLDC with Magnets | Traditional AC Motors |

|---|---|---|

| Field Source | Permanent domains in magnet | Induced by stator currents |

| Efficiency | Over 80% | Under 50% |

| Energy Losses | Minimal eddy currents | High heat from induction |

| Noise | Low, no brushes | Higher from mechanical parts |

| Lifespan | Decades, no wear | Shorter due to heat degradation |

Types of Magnets in BLDC Ceiling Fans

Most energy-efficient ceiling fans on the market today use BLDC motors, with permanent magnets as the primary distinction between BLDC technology and traditional AC induction motors. Permanent magnets provide a stable magnetic field without requiring additional power. When interacting with the electronically controlled stator magnetic field, the motor achieves highly efficient, precise, and quiet operation. In simple terms, this can boost motor efficiency from 50% to over 80%.

In BLDC fan applications, ferrite and neodymium magnets dominate the market, with each type customizable to meet specific requirements.

Ferrite magnets: Ferrite magnets are made from raw materials such as iron oxide, strontium oxide, and barium oxide, featuring low manufacturing costs, excellent corrosion resistance, and good stability. They are widely used in mid-to-low-end and mainstream energy-efficient fans. Although ferrite magnets lag neodymium magnets in magnetic strength, they fully meet torque requirements for home fans and deliver an optimal blend of performance and affordability. Data from IEEE Materials Science indicate that ferrite magnets exhibit 95% corrosion resistance at room temperature.

Neodymium magnets: Composed of neodymium, iron, and boron, these are currently the highest-performing type of commercial magnets in terms of magnetic properties. Their high magnetic energy product allows fans to be designed more compactly and lightweight while meeting exact magnetic requirements. They are an ideal choice for high-end, high-performance ceiling fans. However, their higher cost limits their applications.

In the past, sintered ferrite magnet rings were typically assembled by manually splicing multiple magnet tiles together. The advantages of this process include strong high-temperature performance and magnetic properties, but it also suffers from low production line efficiency and poor machine reliability. Overheated adhesives may degrade under high temperatures, leading to magnet tiles detaching after several years of use.

To achieve efficient mass production, we have developed an integrated injection molding solution. Ferrite powder and thermoplastic materials such as nylon are injected into pre-prepared rotor pole ring molds under high temperature and pressure. The key feature of this technology is the embedded magnet design in the pole-ring rotor mold body, which significantly simplifies the production steps for fan motors. No manual adjustment of pole extremes is needed. Through one-piece molding, the rotor yoke and fixed poles are combined into a compact, high-strength structure, making it highly suitable for large-scale production. It complies with ISO 9001 quality management system certification.

| Magnet Type | Material | Cost Level | Magnetic Energy Product | Durability | Ideal Applications |

|---|---|---|---|---|---|

| Ferrite | Iron oxides | Low | 0.8-4.1 MGOe | High corrosion resistance | Mid-range home and commercial fans |

| Neodymium | Rare earth | High | 33-53 MGOe | Temperature-sensitive, needs coating | Premium, compact high-end models |

Key Advantages of Our Magnets

Our ceiling fan magnets offer procurement teams a prime opportunity for innovative upgrades. They address key challenges in residential and commercial ceiling fans, including high energy consumption, excessive noise, uneven airflow, and a short service life. We invite you to request samples and personally verify their advantages in your product designs. Our over 20 years of industry experience is the reliable assurance that helps your products easily achieve India’s BEE certification and global ISO 9001 compliance!

| Benefit | Our BLDC Magnets | Traditional AC Motors | Impact |

|---|---|---|---|

| Energy Savings | Up to 70%+ reduction | Below 50% efficiency | Cuts operational costs significantly |

| Noise Level | Below 30 dB, no brushes | 40-50 dB with mechanical parts | Whisper-quiet operation for user comfort |

| Airflow Quality | Steady, pulse-free airflow | Jerky, pulsating airflow | Natural breeze-like experience |

| Lifespan | 50,000+ hours, no wear | ~15,000 hours, prone to wear | 3x longer, reducing replacements |

- Ultimate Energy Savings (Up to 70%+): Permanent magnets provide a strong, stable magnetic field, eliminating induction losses of AC motors. Efficiency exceeds 70%, significantly reducing electricity costs.

- Superior Quiet Operation: BLDC designs eliminate brushes and gears, removing friction noise and sparks. Fans operate quietly, ideal for homes and offices.

- Smoother, Stronger Airflow: Constant torque ensures uniform rotation, delivering steady, natural airflow without disruptive pulses.

- Ultra-Long Lifespan: Magnetic drive avoids mechanical wear; magnets maintain strength for decades, reducing maintenance costs. Accelerated life tests show these magnets withstand 50,000 hours of continuous operation.

Magnet Grades and Performance

The magnet grade relates to many critical characteristics that ensure reliable operation of BLDC fan motors in both standard and harsh environments. Please select the appropriate magnet grade based on your climate conditions and performance requirements. We sincerely invite you to request our grade comparison table to make your decision even easier.

Magnet grades consist of magnetic powder combined with polymer binders, designed to strike a balance between magnetic strength and durability. The FA11 & FA15 grades are suitable for very basic applications, but they carry a risk of demagnetization when temperatures exceed 120°C. For default standard fans, our recommended magnet grade is FA19, because it not only offers 150°C thermal resistance but also moderate magnetic strength, ensuring no performance degradation in general working environments. According to ASTM testing standards, FA19 can still maintain 95% of its magnetic strength even in high-temperature conditions.

FA20T and higher grades can withstand higher operating temperatures, capable of withstanding 180°C working environments, making them the optimal choice for manufacturing industrial fans.

| Grade | Br | HCB | HcJ | (BH)max | Melt Flow Rate | IZOD Impact Strength | Tensile Strength | Flexural Strength | Composition | ||||

| mT | Gs | kA/m | Oe | kA/m | Oe | kJ/m3 | MGOe | g/10min | kJ/m² | MPa | MPa | ||

| FA11 | 213 | 2130 | 162 | 2040 | 279 | 3500 | 8.80 | 1.10 | 100 | 50 | 85 | 160 | Ferrite+PA6 |

| FA15 | 245 | 2450 | 183 | 2300 | 251 | 3150 | 11.90 | 1.50 | 80 | 35 | 85 | 165 | |

| FA19 | 284 | 2840 | 195 | 2450 | 235 | 2950 | 15.60 | 1.96 | 120 | 19 | 90 | 170 | |

| FA20T | 293 | 2930 | 193 | 2420 | 223 | 2800 | 16.60 | 2.08 | 80 | 15 | 85 | 160 | |

| FA22T | 305 | 3050 | 191 | 2400 | 229 | 2870 | 18.10 | 2.27 | 50 | 11 | 80 | 145 | |

| FB12 | 227 | 2270 | 171 | 2150 | 279 | 3500 | 10.00 | 1.26 | 150 | 30 | 57 | 108 | Ferrite+PA12 |

| FB16 | 258 | 2580 | 193 | 2430 | 255 | 3200 | 13.10 | 1.64 | 110 | 25 | 62 | 110 | |

| FB19R | 283 | 2830 | 205 | 2570 | 255 | 3200 | 15.50 | 1.95 | 90 | 20 | 56 | 110 | |

| FB20RT | 294 | 2940 | 203 | 2550 | 247 | 3100 | 16.70 | 2.10 | 90 | 15 | 49 | 90 | |

| FB23R | 306 | 3060 | 209 | 2630 | 253 | 3180 | 18.00 | 2.26 | 50 | 12 | 50 | 93 | |

| FC14 | 242 | 2420 | 175 | 2200 | 271 | 3400 | 11.30 | 3.35 | 150 | 13 | 70 | 130 | Ferrite+PPS |

| FC15 | 250 | 2500 | 179 | 2250 | 247 | 3100 | 12.10 | 3.44 | 195 | 9 | 55 | 110 | |

| FC16B | 256 | 2560 | 178 | 2234 | 239 | 3000 | 12.70 | 3.54 | 260 | 9 | 55 | 110 | |

| FC17 | 268 | 2680 | 177 | 2226 | 218 | 2736 | 13.70 | 3.61 | 128 | 8 | 50 | 100 | |

Magnet Specifications

Our injection-molded ferrite ring magnets are specifically designed for BLDC motors, with specifications meeting diverse fan application requirements. They ensure compatibility for household and commercial fans across various operating environments. Download our catalog today to find the perfect magnetic ring for your product.

| Specification | Range/Details | Common Examples |

|---|---|---|

| Outer Diameter (OD) | 50-155mm | OD152.52, OD120, OD52 |

| Inner Diameter (ID) | Varies with OD | ID135, ID101, ID86.2 |

| Height (H) | 20-25mm | H24, H22, H20 |

| Pole Count | 10-16 poles | 16 poles, 14 poles, 10 poles |

| Grade | FA19-FA22 | FA19 (standard), FA22T (premium) |

| Flux Density | 1.0-1.5 Tesla | 1.2 T (ferrite), 1.4 T (neodymium) |

Examples:

- OD152.52xID135x24-16 poles

- OD152.3xID133.6×24-16 poles

- OD152.3xID133.6×20-16 poles

- OD152xID133.6×24.8-16 poles

- OD152xID133x22.5-14 poles

- OD152xID132.7×24-16 poles

- OD152xID132.2×25-16 poles

- OD152xID131x24-16 poles

- OD120xID101x25-14 poles

- OD113.5xID94.2×22-10 poles

- OD102.8xID86.2×25-10 poles

- OD52xID133.3×22-16 poles

Magnetization Direction

Multi-pole radial magnetization technology can significantly enhance the energy efficiency of BLDC ceiling fan motors. You can flexibly configure the pole count of the magnet ring based on different wind speeds and torque requirements to optimize motor design. If interested, feel free to contact us. We provide customized magnet ring performance reports to help upgrade the performance of your brushless DC ceiling fans.

In BLDC motors, permanent magnets are radially magnetized along the magnet ring, with N and S poles arranged alternately. The magnetic field acts perpendicular to the motor stator surface. The lower reluctance value allows magnetic flux to easily pass through the air gap between the stator and rotor, generating greater electromagnetic force and thus producing higher output torque.

The greater the number of poles, the smaller the pole pitch. A smaller pole pitch divides rotation into finer mechanical steps, resulting in smoother coil switching transitions. This reduces torque fluctuations, minimizes vibration and noise levels, and delivers a seamless user experience.

Compared to single-pole magnetization technology, the radial multi-pole design allows magnetic flux to flow more completely through the magnets, reducing heat loss by 10-15%. This ensures superior fan efficiency, which is especially critical for high-speed and variable-speed fans. We guarantee precise pole alignment in every production process for millions of units, enabling seamless integration with downstream automated assembly lines.

| Magnetization Type | Pole Count | Vibration Reduction | Torque Density | Best Use Case |

|---|---|---|---|---|

| Radial Multi-Pole | 10-16 poles | 15% less with 16 poles | High (compact designs) | High-performance fans |

| Axial/Single-Pole | 2-4 poles | Higher vibration | Lower | Basic, low-cost motors |

Packaging Standards

Our packaging ensures magnet integrity during transport and storage, addressing procurement concerns about damage, delays, or magnetic interference. We serve both small and large orders for residential and commercial fan manufacturers. Customize packaging solutions based on order volume. These standards comply with IATA transport regulations, ensuring safe global delivery.

Each magnet is individually wrapped in bubble wrap or foam to prevent collisions and magnetic interference. Bulk orders are packed in high-strength corrugated cartons, filled with foam or paper padding to eliminate movement. External galvanized iron or metal boxes minimize magnetic fields, ensuring safe handling and compliance with transport regulations. Each carton is clearly labeled with product model, quantity, and handling instructions.

Sample Orders: Shipped via FedEx or UPS in reinforced cartons, designed to withstand pressure and weather changes, ensuring fast, trackable delivery.

Bulk Orders: Packed in ISPM 15-compliant wooden or plywood crates, reinforced with steel bands and waterproof liners for long-distance transport durability. We also provide real-time tracking to minimize delay risks.

| Order Type | Packaging Method | Protection Features | Delivery Time | Cost Efficiency |

|---|---|---|---|---|

| Samples | Reinforced cartons, foam wrapping | Magnetic shielding, shockproof | 3-7 days (express) | Higher per unit |

| Bulk | Wooden crates, steel bands | Waterproof, magnetic shielding | 2-4 weeks (sea) | Lower per unit |

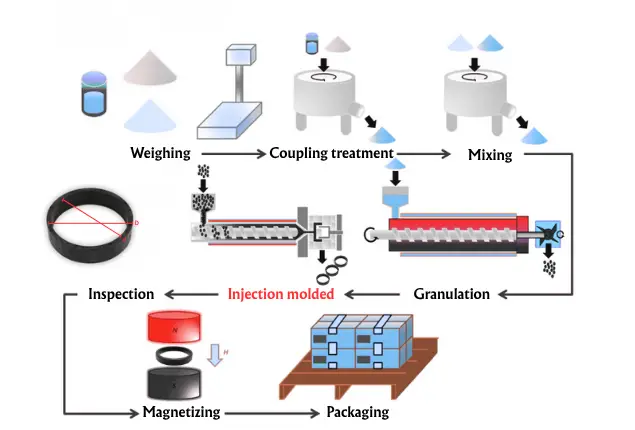

Manufacturing Process of Ceiling Fan Magnets

The injection molding process uniformly mixes ferrite powder with thermoplastic binder under high temperature and pressure, then injects the compound into a precision mold cavity.

As the core of injection molding, the mold not only ensures micron-level precision in rotor dimensions for seamless integration and smooth operation, but also forms isolated structures to guide accurate N/S pole alignment during magnetization. The resulting stable magnetic poles effectively eliminate torque ripple, reduce noise, maintain energy efficiency, and ensure million-unit consistency, perfectly suited for automated assembly lines.

To further lower the barrier for customers, we stock over 100 standard molds covering mainstream specifications. We also provide digital simulation preview tools to quickly verify compatibility and minimize design iterations.

Custom Magnet Solutions

Customization Steps:

- Submit detailed motor specifications and performance goals.

- We match your requirements with our 100+ existing molds or design new ones.

- Produce and test prototypes to validate fit, efficiency, and durability in your motor assembly.

Custom magnets address unique challenges, such as ultra-compact designs, extreme temperatures, or high-speed requirements. By optimizing pole count and grade, we enhance motor efficiency and reduce noise, giving your fan a competitive edge in premium or niche markets.

Frequently Asked Questions (FAQ)

- How does pole count affect performance? Higher pole counts reduce vibration by 15%, improving smoothness.

- Can these magnets withstand extreme heat? FA22T maintains performance at 180°C, ideal for harsh climates.

- What if my design requires unique specifications? We can customize magnets in 4 weeks.

- How are magnets protected during shipping? Foam wrapping and magnetic shielding ensure 99.9% safe delivery.

- What’s the minimum order quantity for customization? Flexible, starting at 500 units.

- Do you offer a performance guarantee? Yes, magnetic strength is warranted for 5 years.

Contact Us: Send your questions via email, and receive personalized answers within 24 hours.