Advanced Rare Earth Magnet Recycling

Rare earth elements, as the cornerstone of modern technology, are indispensable in green energy, electric vehicles, wind power, and high-end electronics, particularly with neodymium magnets at their core. However, the environmental cost of rare earth mining is high, and the geopolitical risks from a highly concentrated supply chain are increasingly evident. The reusing of rare earth magnets not only greatly cuts down on production costs but also mitigates environmental damage enhances supply chain resilience and extends resource lifecycles. With such new technologies as HyProMag’s HPMS process, the recycling of rare earth is turning into a primary road to the achievement of green supply and economic gains. Permanent magnets, including neodymium magnet, samarium-cobalt, and alnico magnet, contain critical rare earth elements.

The Strategy of Rare Earth Element Recycling

Rare earth elements are a group of chemical elements, including lanthanides, scandium, and yttrium, with praseodymium and neodymium being particularly important in industrial applications. Concentrations in natural ores are typically below 5%. This makes discarded magnets a high-value “urban mine.” Recycling is the process by which these rare earth materials can be reintroduced into the production cycle, thus creating a closed-loop economic system. On the other hand, the manufacturing process of neodymium magnets is extremely complex, involving the extraction and refining of rare earth elements. The production process includes ore mining, chemical separation, alloy preparation, and magnet forming, which are energy-intensive and require large amounts of chemical reagents, easily leading to ecological damage and resource pollution., which results in the destruction of the ecology and the pollution of resources. Furthermore, the supply chain for rare earth across the world is mostly in China (the country accounts for more than 80% of production). Hence, it is susceptible to changes in the geopolitical environment and trade restrictions that might lead to supply interruptions and price fluctuations.

Rare earth elements are a group of chemical elements, including lanthanides, scandium, and yttrium, with praseodymium and neodymium being particularly important in industrial applications. Concentrations in natural ores are typically below 5%. This makes discarded magnets a high-value “urban mine.” Recycling is the process by which these rare earth materials can be reintroduced into the production cycle, thus creating a closed-loop economic system. On the other hand, the manufacturing process of neodymium magnets is extremely complex, involving the extraction and refining of rare earth elements. The production process includes ore mining, chemical separation, alloy preparation, and magnet forming, which are energy-intensive and require large amounts of chemical reagents, easily leading to ecological damage and resource pollution., which results in the destruction of the ecology and the pollution of resources. Furthermore, the supply chain for rare earth across the world is mostly in China (the country accounts for more than 80% of production). Hence, it is susceptible to changes in the geopolitical environment and trade restrictions that might lead to supply interruptions and price fluctuations.

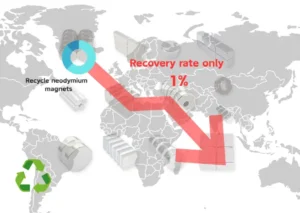

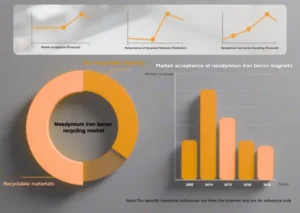

The recycling of rare earth magnets is one of the most feasible ways to solve the above problems. Recycling, by means of taking out NdFeB magnets from discarded electronics, end-of-life vehicles, and industrial equipment, lessens the reliance on new mining, cuts down on production costs, and improves resource efficiency.

The Challenges of Rare Earth Magnet Recycling

Rare earth magnet recycling has become the foundation of the clean energy sector, which provides considerable capacity to green the environment, decrease the risk of input materials’ disruptions, and enhance the duration of rare earth materials. Although recycling neodymium magnets holds a lot of economic and ecological potential, the actual implementation is still riddled with difficulties.

1. Low Recycling Rates

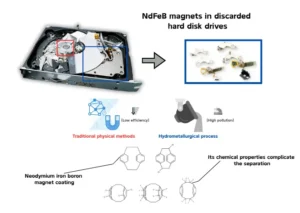

2. Technical Challenges in Separation

NdFeB magnets are typically coated with nickel, zinc, or epoxy resin to prevent corrosion, and these coatings are difficult to remove during recycling. Additionally, many magnets are fixed in products with complex adhesives, which further complicates separation due to their chemical properties.

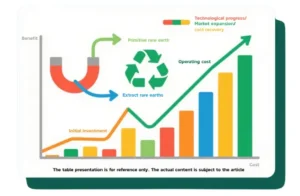

3. Economic Barriers to Recycling

4. Market Acceptance and Quality Concerns

Rare Earth Magnet Recycling Technologies

Traditional recycling methods such as direct reuse, hydrometallurgy, and pyrometallurgy have laid the foundation, but their high energy consumption and environmental pollution limit widespread adoption. In recent years, emerging technologies like bioleaching, ionic liquid extraction, and hydrogen processing are reshaping the rare earth recycling landscape, promoting industry development with higher efficiency and lower carbon footprints.

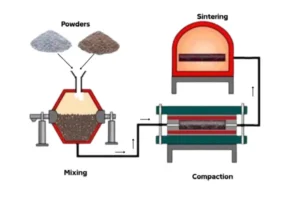

1. Direct Reuse and Powder Metallurgy

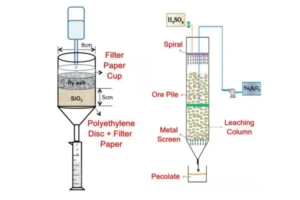

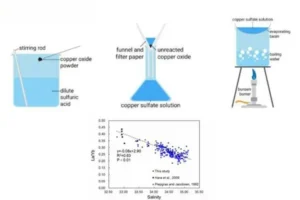

2. Hydrometallurgy: Acid Leaching and Solvent Extraction

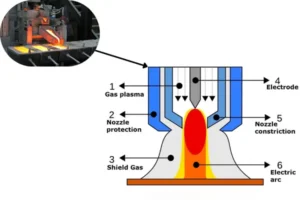

3. Pyrometallurgy: High-Temperature Processing and Plasma Arc

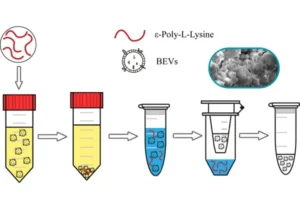

4. Bioleaching: Microbial Extraction

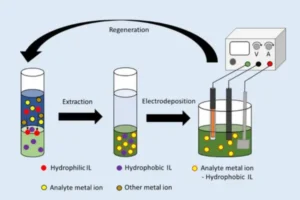

5. Ionic Liquid Extraction

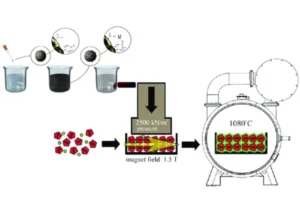

6. Hydrogen Processing of Magnet Scrap (HPMS)

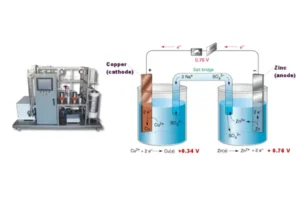

7. Supercritical CO2 and Electrochemical Methods

8. Copper Salt Method

Summary: The long-term value of rare earth recycling

The EU’s REE silience project estimates that by 2030, recycling could meet 15-20% of Europe’s rare earth demand, while the U.S. ReCycle project aims to achieve 10% self-sufficiency in neodymium by 2027. Recycled magnets cost 20-30% less than mined ones, making rare Earth recycling a core pillar of the circular economy and a long-term solution for sustainability. The EU’s Critical Raw Materials Act mandates that 15% of rare earth demand be met through recycling by 2030, and China’s Circular Economy Development Plan is also advancing the industrialization of rare earth recycling. Growing consumer awareness is creating market demand for recycling, and in the long term, rare earth recycling not only supports net-zero emission goals but also drives sustainable economic growth through efficient resource use.

I'm dedicated to popular science writing about magnets. My articles mainly focus on their principles, applications, and industry anecdotes. Our goal is to provide readers with valuable information, helping everyone better understand the charm and significance of magnets. At the same time, we're eager to hear your opinions on magnet-related needs. Feel free to follow and engage with us as we explore the endless possibilities of magnets together!