Magnetic Couplings: Power Transmission Without Contact

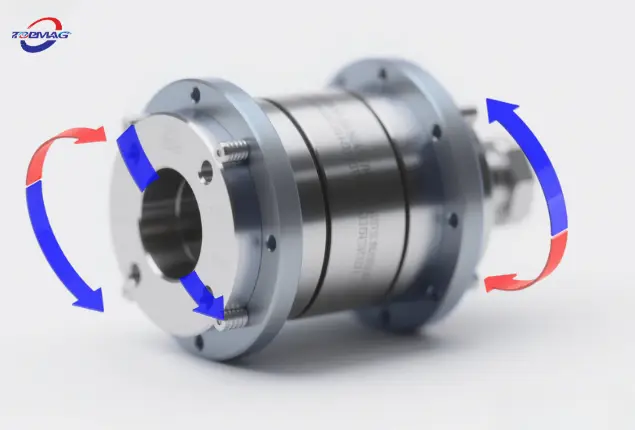

A magnetic coupling employs the power of magnetic fields to transfer torque without any physical contact. Power is thus transmitted through the magnetic coupling between the inner and outer rotors without frictional losses or wear. This invention radically changes the conception of the old mechanical couplings, allowing the changing of the rotary seals into non-rotary seals and the obtaining of a leak-free power transmission.

A magnetic coupling employs the power of magnetic fields to transfer torque without any physical contact. Power is thus transmitted through the magnetic coupling between the inner and outer rotors without frictional losses or wear. This invention radically changes the conception of the old mechanical couplings, allowing the changing of the rotary seals into non-rotary seals and the obtaining of a leak-free power transmission.

Material Selection

Magnet

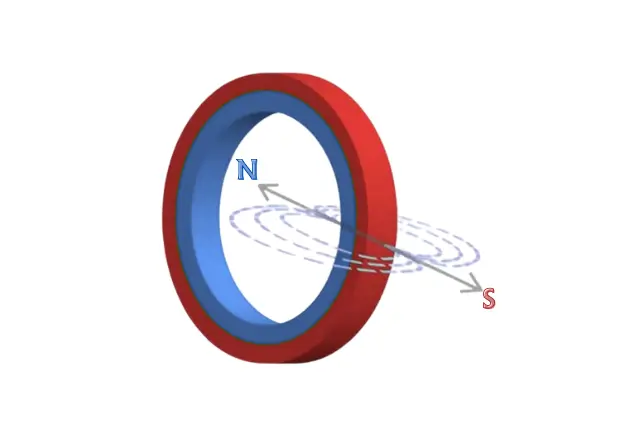

A coaxial magnetic coupling is made up of an outer rotor, an inner rotor, a spacer sleeve, and a precision bearing system. Both the inner and outer rotors have permanent magnets implanted in them, which are arranged alternately in terms of their north and south poles along their circumference, thus producing a strong magnetic field. In order for the magnetic field to effectively couple between the two rotors, the spacer sleeve, which is generally non-magnetic, is used for this purpose. The bearing system is the component that keeps the rotor stable when operating at high speeds.

A coaxial magnetic coupling is made up of an outer rotor, an inner rotor, a spacer sleeve, and a precision bearing system. Both the inner and outer rotors have permanent magnets implanted in them, which are arranged alternately in terms of their north and south poles along their circumference, thus producing a strong magnetic field. In order for the magnetic field to effectively couple between the two rotors, the spacer sleeve, which is generally non-magnetic, is used for this purpose. The bearing system is the component that keeps the rotor stable when operating at high speeds.

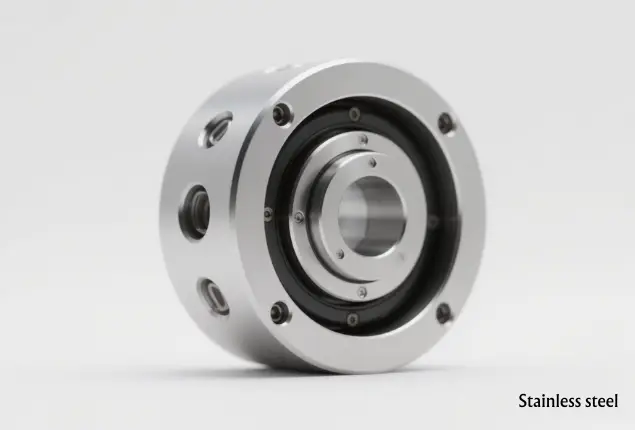

Housing materials

The housing materials should be mechanically strong and at the same time resistant to corrosion. Common options include:

Stainless steel: SUS316 offers excellent anti-magnetic and pressure resistance, making it suitable for high-pressure or corrosive environments; 304/316L are widely used in general industrial applications.

PVC: Extremely corrosion-resistant and suitable for use in strong acid and alkaline environments, but with lower mechanical strength, it’s ideal for low-pressure applications.

Customization Options: Hermetic welding or composite materials can be used upon request to enhance protection further.

Coaxial Magnetic Couplings

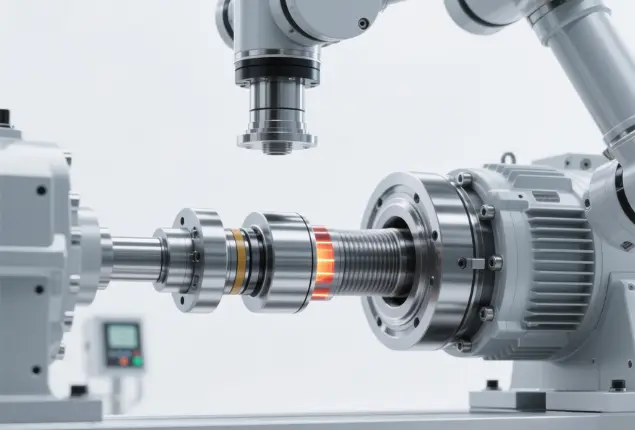

The synchronous transmission of coaxial magnetic couplings represents their leading benefit. The inner and outer rotors reach slip-free power transmission via the magnetic field coupling. With a torque of up to 84 Nm, they fit applications with high torque demands. Their non-contact design makes them completely free of lubrication, eliminating all issues related to wear or leakage that usually characterize couplings. For this reason, a high degree of tolerance to shaft misalignment is realized, along with much more installation flexibility.

In magnetic drive pumps, the most modern and widespread applications of coaxial magnetic couplings are found in the chemical, pharmaceutical, food processing, and vacuum equipment industries. They are used in processes where zero leakage is preferred for corrosive, toxic, or flammable fluids.

Disc Magnetic Couplings

These couplings are compact and allow a maximum torque of 18.5 Nm. They have an excellent feature concerning installation, as there can be a maximum angular misalignment of 3° or 1/4 inch of parallel misalignment, which makes them very useful for applications where shaft alignment is not easy to accomplish. Because this uses planar magnetic attraction, smaller air gaps increase torque, but since the discs do not have much surface area, overall torque capacity is low.

Disc magnetic couplings are widely used in magnetic stirrers and small magnetic-driven pumps, particularly in mixing systems for laboratory equipment, biopharmaceuticals, and food processing.

Technical Advantages

Contactless and Wear-Free: The lack of physical contact eliminates friction and wear, extending equipment life.

Zero Leakage: Power is transmitted via a magnetic field, and the isolation barrier provides a complete seal, preventing liquid or gas leakage.

Low Noise and Low Vibration: The lack of mechanical contact ensures smooth operation, significantly reducing noise and vibration, and improving the working environment.

Through-Wall Power Transmission: The magnetic field can penetrate non-magnetic materials, making it suitable for applications that isolate the drive and driven components.

Torque Limiting: When the load exceeds the designed torque, the magnetic coupling automatically “slips,” protecting the system from overload damage.

Easy Installation: High tolerance for shaft misalignment simplifies installation and reduces precision requirements.

The lifespan of magnetic couplings largely depends on the operating conditions, the load cycle, and the quality of maintenance, and usually varies from 15 to 30 years. The component’s wear is substantially minimized due to the non-contact design, while using high-grade permanent magnet materials and safety provisions to extend its lifetime.

Industries

Energy saving as well as a reduction in vibrations to an appreciable extent are the most prominent features of magnetic couplings, which are utilized in such diverse industries as:

Water treatment: Water is used to pump wastewater and mix chemicals.

Chemical and petroleum: The technology has been used for handling corrosive or flammable liquids.

Food and pharmaceutical: For maintaining purity, non-contamination, and power transmission.

Marine and HVAC: For the provision of sealed, trouble-free drives.

Mining and cement: To satisfy the extreme torque needs in rugged areas.

Customized Solutions

Due to its collaboration with specialized manufacturers, TOPMAG providers can configure the coupling for the type of magnet, housing material, and dimensional design. It is part of what manufacturing companies offer free of charge: technical advice and design solutions.

The selection of a magnetic coupling requires a complete review of the following:

Torque requirements: specify either coaxial or disc coupling, depending on load.

Operating conditions: temperature, corrosive conditions, and pressure must all be considered.

Installation space: disk couplings are applicable in confined spaces, while coaxial couplings are applicable where high torque is required.

Quality standards: available industrial certifications must be considered.

I'm dedicated to popular science writing about magnets. My articles mainly focus on their principles, applications, and industry anecdotes. Our goal is to provide readers with valuable information, helping everyone better understand the charm and significance of magnets. At the same time, we're eager to hear your opinions on magnet-related needs. Feel free to follow and engage with us as we explore the endless possibilities of magnets together!