The Ultimate Guide to Ceiling Fan Noise

The noise issue with ceiling fans has plagued billions of households worldwide, emerging as a critical technical challenge for manufacturers. Injection-molded magnetic rings are specifically engineered to resolve loosening inside the motor and magnetic field fluctuations caused by the aging of traditional arc magnet bonding processes, effectively eliminating persistent low-frequency electromagnetic “humming.” However, these solutions are targeted only at magnetic noise and are ineffective against mechanical issues such as impeller vibration, bearing wear, looseness in the drive system. Before implementing a targeted solution, it is recommended to first conduct a systematic diagnosis of the root cause of the noise.

The noise issue with ceiling fans has plagued billions of households worldwide, emerging as a critical technical challenge for manufacturers. Injection-molded magnetic rings are specifically engineered to resolve loosening inside the motor and magnetic field fluctuations caused by the aging of traditional arc magnet bonding processes, effectively eliminating persistent low-frequency electromagnetic “humming.” However, these solutions are targeted only at magnetic noise and are ineffective against mechanical issues such as impeller vibration, bearing wear, looseness in the drive system. Before implementing a targeted solution, it is recommended to first conduct a systematic diagnosis of the root cause of the noise.

As a classic summer cooling appliance with a long history, ceiling fans are widely popular worldwide, particularly for their ultra-low energy consumption. In hot climates like India, Brazil, Southeast Asia, and the Middle East, penetration rates exceed 90%. According to the International Energy Agency (IEA), ceiling fans account for just 3% of household appliance electricity consumption yet deliver up to 70% natural cooling efficiency. Unfortunately, after 3–5 years of use, noise becomes nearly inevitable: bearing wear, blade imbalance, and other factors intensify buzzing that not only disrupts user experience but also poses safety risks. To tackle this systematically, the first step is clear: where exactly is the noise coming from?

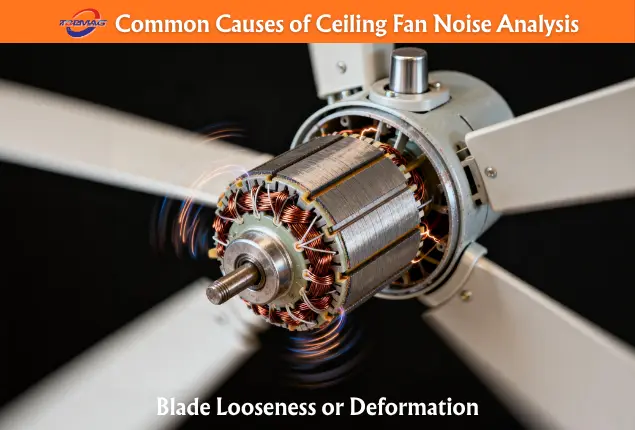

Common Causes of Ceiling Fan Noise Analysis

Friction noise often emerges quietly after several years of ceiling fan use, disrupting daily life and rest. These issues arise from the long-term cumulative effects of mechanical wear, environmental erosion, and design flaws. According to the international standard IEC 60879, compliant ceiling fans should have noise limits below 35 dB, but many older products easily exceed this. Through the following self-diagnostic guide, you can initially locate and address these common issues.

Dust buildup is a common trigger that increases wind resistance and produces a low-pitched hum. When blades and frames are covered in dust, gently wipe them with a damp cloth and check if the noise disappears after they are completely dry. If the problem persists, further clean the motor housing’s heat dissipation vents.

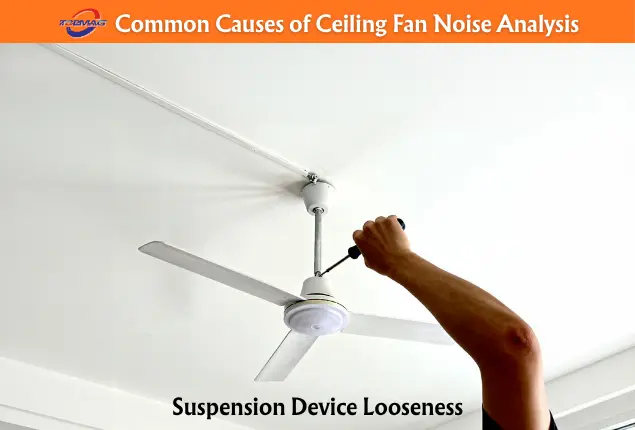

If intermittent “clicking” impact sounds are heard during operation, this is usually due to screws in the hanging rod or suspension device loosening from prolonged vibrations, transmitting mechanical noise to the ceiling and amplifying it throughout the room. Continuous stress accumulation reduces system stability and increases safety risks. You can first turn off the power and gently shake the hanging rod to check for obvious wobbling. If looseness is confirmed, use a screwdriver to evenly tighten all connecting screws for initial relief.

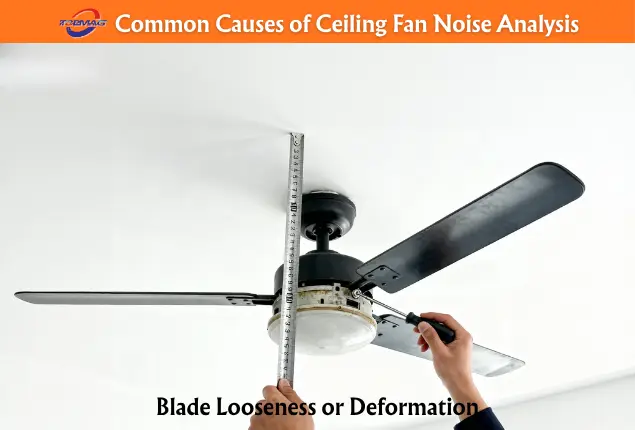

Loose blade fixing screws can cause air turbulence interference, producing high-frequency “buzzing” vibration sounds. In an imbalanced state, the motor load increases significantly, accelerating overall wear. You can use a ruler to measure the distance from the tip of each blade to the ceiling. if the height difference exceeds 2 millimeters, tighten the screws with a screwdriver and adjust to level consistency. For deformed blades, it is recommended to have them replaced by professionals.

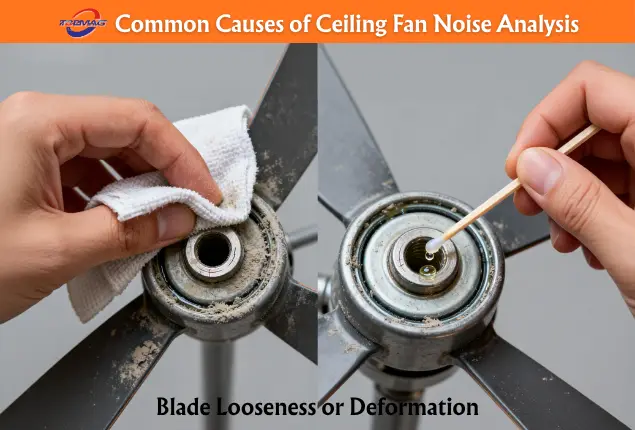

In high-temperature environments, the lubricant grease inside bearings gradually evaporates and dries up, increasing friction and changing the running sound from smooth airflow to a “squeaking” frictional hum. If the noise intensifies a few minutes after startup, this likely points to a bearing issue. Wipe dust from the bearing surface with a damp cloth, then apply a small amount of precision machine oil to the shaft center with a toothpick, let it sit for 1 minute, and test. If severely worn, the bearing must be replaced to avoid motor overheating damage.

The magnets inside ceiling fan motors act as permanent magnets to drive rotor rotation, and the periodic changes in magnetic flux naturally produce electromagnetic humming. Especially when traditional bonded arc magnet loosen, it exacerbates magnetic field fluctuations, leading to noticeable “buzzing” sounds and amplified vibrations. You can check the motor housing for abnormal vibrations. If the hum persists, it usually indicates the need for professional inspection to assess magnetic field stability.

Magnetic Solutions

When magnetic core flux generates noise and methods such as cleaning, tightening, and lubrication prove ineffective, injection-molded magnetic rings may provide a solution.

Traditional Bonded Ring Magnet:

Multiple independent arc-shaped magnets are bonded to the motor housing with adhesive. Under high-temperature, high-RPM, and frequent start-stop conditions, the adhesive is prone to aging and failure. Even micron-level displacement of the arc magnets disrupts magnetic field uniformity, producing electromagnetic humming and triggering mechanical vibration.

Injection-Molded Ring Magnet:

Under a strong magnetic field, magnetic powder particles are precisely oriented along the circumferential direction and formed in one injection molding process. This creates a seamless and continuous ideal magnetic field inside the ring, with extremely high structural integrity, fundamentally eliminating magnet displacement and ensuring ultimate magnetic field stability and quietness throughout the motor’s lifecycle.

| Indicator | Traditional Ring Bonded Magnet | Injection-Molded Ferrite Magnetic Ring |

|---|---|---|

| Stability | Prone to shifting, offset rate 10% | One-piece fixation, offset <1% |

| Noise Reduction | Basic reduction of 5% | Reduction of 15%-20% |

| Compatibility | Limited to specific designs | Universal for 90% of motors |

| High-Temp Tolerance | Efficiency drops 20% after evaporation | Stable up to 80°C |

Please contact our technical support team immediately to apply for free samples and conduct comprehensive testing. We will provide you with an exclusive “Injection-Molded Magnet Ring Grade Parameter Table” to assist your decision-making with specific data.

FAQ Summary

What are the main causes of ceiling fan noise? The main causes include dust accumulation, suspension device looseness, blade imbalance, bearing wear, and the most fundamental motor magnet fluctuations and displacements.

How can cleaning dust reduce buzzing? Use a wrung-out damp cloth to carefully wipe both sides of the blades and the frame, then restart and test after thoroughly drying.

How should suspension device looseness be handled? After cutting off power, lightly shake the hanging rod to check stability. If looseness is found, use a screwdriver to evenly tighten all screws.

What are simple handling methods for bearing abnormalities? After wiping off dust, try dripping a small amount of precision machine oil into the bearing center, let it sit for 1 minute, and then test. If the noise does not subside, consider replacing the bearing.

What is the injection-molded magnet ring solution? It is a ferrite magnet ring manufactured using a one-time injection molding process that can be seamlessly integrated into the motor, achieving a silent upgrade by eliminating arc magnet displacement.

What are the core advantages of injection-molded magnet rings? Its core advantage lies in the ultra-high stability brought by the integrated structure, which can effectively reduce magnetic noise by 15%-20% and significantly extend product lifespan.

I'm dedicated to popular science writing about magnets. My articles mainly focus on their principles, applications, and industry anecdotes. Our goal is to provide readers with valuable information, helping everyone better understand the charm and significance of magnets. At the same time, we're eager to hear your opinions on magnet-related needs. Feel free to follow and engage with us as we explore the endless possibilities of magnets together!