Common Causes of Ceiling Fan Wobbling

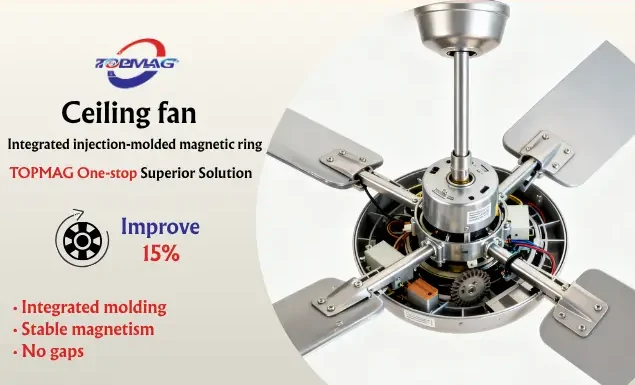

Ceiling fan wobbling is commonly caused by blade imbalance, improper installation, or manufacturing deviations. If not addressed promptly, it will lead to long-term instability. The integrated injection-molded magnetic ring serves as an innovative solution for rotor and stator faults in motors, reducing friction-induced wobbling and improving efficiency by 15%. However, it is only suitable for rotor-related issues and not for blade deformation or loose installation. It is recommended to first systematically check the causes and then select the appropriate countermeasures to ensure safety and efficiency.

Ceiling fan wobbling is commonly caused by blade imbalance, improper installation, or manufacturing deviations. If not addressed promptly, it will lead to long-term instability. The integrated injection-molded magnetic ring serves as an innovative solution for rotor and stator faults in motors, reducing friction-induced wobbling and improving efficiency by 15%. However, it is only suitable for rotor-related issues and not for blade deformation or loose installation. It is recommended to first systematically check the causes and then select the appropriate countermeasures to ensure safety and efficiency.

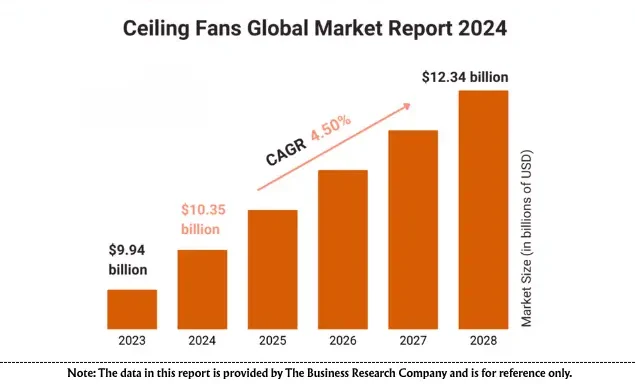

Ceiling fans are widely used in residential and commercial environments, providing reliable ventilation. They are especially beneficial in tropical and subtropical regions, improving air quality and reducing stuffiness. According to the Straits Research 2024 Ceiling Fan Market Report, the global ceiling fan market is projected to reach $13.58 billion in 2025, with Asia dominating at 52% market share. Wobbling faults are commonly reported in industry reports. To ensure stable operation, fans must be installed on poured concrete ceilings or solid wood ceilings at least 10mm thick, with a load-bearing capacity of no less than 50kg.

Ceiling fans are widely used in residential and commercial environments, providing reliable ventilation. They are especially beneficial in tropical and subtropical regions, improving air quality and reducing stuffiness. According to the Straits Research 2024 Ceiling Fan Market Report, the global ceiling fan market is projected to reach $13.58 billion in 2025, with Asia dominating at 52% market share. Wobbling faults are commonly reported in industry reports. To ensure stable operation, fans must be installed on poured concrete ceilings or solid wood ceilings at least 10mm thick, with a load-bearing capacity of no less than 50kg.

Common Wobbling Phenomenon in Household Ceiling Fans

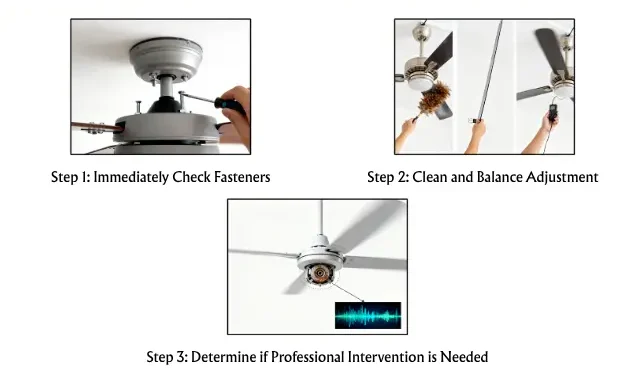

When wobbling or unusual noise occurs, follow this 3-step troubleshooting process to resolve 80% of issues in 10 minutes.

Step 1: Immediately Check Fasteners After turning off the power, use your hand or a screwdriver to inspect and tighten all visible screws one by one, including the canopy screws connecting to the ceiling, blade-to-motor housing screws, and light fixture screws. tightening them eliminates most severe wobbling and “clicking” impact sounds immediately.

Step 2: Clean and Balance Adjustment

With power OFF, use a feather duster or soft cloth to wipe both sides of all blades dust-free.

Then perform simple balancing:

1.Clip balance clip sequentially to the middle of each blade, test to find the least wobbly blade.

2.On that blade, slide clip, locate minimal shake point.

3.Power ON test, if wobbling decreases, position is correct.

This quick method balances blades, fixing “trembling” from minor deformation or dust.

Step 3: Determine if Professional Intervention is Needed If wobbling persists after the above steps, accompanied by sharp “whining” from the motor or irregular stuttering, stop self-handling immediately. This likely involves internal bearing rust or motor failure.

Please contact after-sales service or a professional technician to avoid safety risks.

| Type | Common Causes | Trouble-shooting Method |

|---|---|---|

| Blade Imbalance | Dust accumulation or minor blade bending | Clean blades, balance adjustment |

| Improper Installation | Loose screws or insufficient load-bearing | Check fixings, stop use and inspect immediately |

| Motor/Environmental | Rotor eccentricity or bearing rust | Lubricate bearings, professional repair |

Multiple Hazards of Ceiling Fan Wobbling

Ignoring wobbling triggers a chain reaction, leading to safety, economic, and equipment lifespan hazards.

Safety Risks: U.S. Consumer Product Safety Commission (CPSC) 2023-2025 data shows nearly 20,000 ceiling fan-related injuries annually in the U.S., with insecure installation and wobbling instability as primary causes. Severe wobbling accelerates structural fatigue, causing fixings to loosen and posing fall hazards.

Economic Losses: To overcome wobbling resistance, the motor outputs an extra 15%-20% power, significantly increasing electricity bills. For 8 hours daily operation, household annual electricity costs may rise by hundreds of yuan.

Shortened Equipment Lifespan: Experiments by Nanyang Technological University in Singapore show that wobbling over 0.5mm increases screw loosening risk by 7 times and accelerates bearing wear, shortening lifespan to 60% of standard.

| Hazard | Direct Impact | Potential Causes |

|---|---|---|

| Energy Efficiency Decline | Electricity bill increase of 10%-20% | Motor continuously overloads to overcome imbalance resistance |

| Equipment Lifespan Shortening | Bearing wear rate 2-3x higher, lifespan ~6 years | Continuous vibration accelerates mechanical fatigue, blade deformation worsens imbalance |

| Safety Risk Escalation | Fall or part ejection hazards, ~20,000 annual incidents | Ceiling mount or screws loosen due to prolonged wobbling |

Magnetic Solutions

For wobbling caused by uneven motor magnetic forces, the integrated injection-molded magnetic ring represents a superior solution.

This approach uses high-performance permanent magnets formed integrally, replacing traditional multi-tile magnetic bonding processes. It generates a uniform, stable magnetic field, fundamentally reducing rotor radial runout for smooth rotation and up to 15% efficiency gains. The solution primarily addresses motor rotor issues and suits most models. For external issues like blade deformation or loose installation, mechanical correction is required first.

| Solution | Advantages | Disadvantages |

|---|---|---|

| Traditional Magnetic Tiles | Lower cost | Adhesive ages, causing magnetic decay and wobbling |

| Injection-Molded Ring | Integral forming, stable magnetism, no gaps | Slightly higher initial investment, but significant long-term benefits |

FAQ Summary

Can I continue using the fan after wobbling? stop use and cut power immediately. Severe wobbling and obvious noise usually indicate loose installation or serious motor failure.

Is the magnetic solution (integrated ring) costly?This is a manufacturing-end design innovation, not an aftermarket retrofit. The ceiling fan manufacturer replaces traditional magnetic tile bonding rings with integrated injection-molded rings.

Does this solution apply to LED ceiling fan lights? Yes, fully applicable. The integrated ring technology greatly improves motor smoothness, reducing wobbling impacts on LED solder joints and driver power supplies.

What if I smell burning during wobbling? Cut power and stop use immediately! The odor may stem from overheated insulation, coil short-circuit, or capacitor damage.

I'm dedicated to popular science writing about magnets. My articles mainly focus on their principles, applications, and industry anecdotes. Our goal is to provide readers with valuable information, helping everyone better understand the charm and significance of magnets. At the same time, we're eager to hear your opinions on magnet-related needs. Feel free to follow and engage with us as we explore the endless possibilities of magnets together!